We are manufacturers and designers of injected plastic parts.

We are your partner

in the manufacturing, design, and development of all types of injected plastic parts. We also have an extrusion process to meet the needs of clients who require it.

Among the services we offer, we have two mold manufacturing workshops.

Contact us

Expert Consulting

3D Prototypes

Mold Manufacturing

Production

Why us?

Machinery and Equipment

We have the ideal machinery, technology, and peripheral equipment for your plastic injection project.

Certified Experience

Our Quality Standards are certified by the National and International ISO-9001:2015 Standard.

Competitiveness

Based on the high efficiency of our production processes, we are a very competitive company in the plastic injection market.

High-Quality Products

Our products are certified by the highest national and international quality standards.

We've been operating since 1983

We are pioneers in high-tech plastic injection in Mexico.

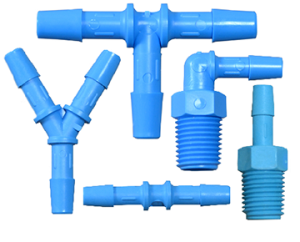

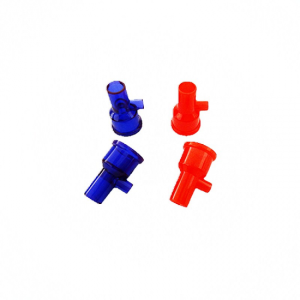

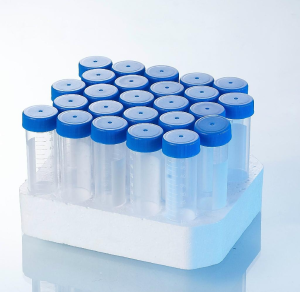

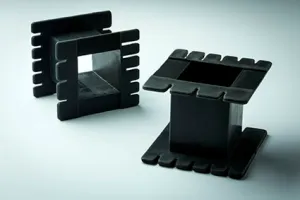

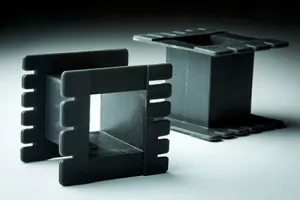

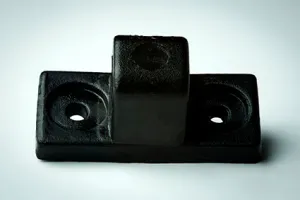

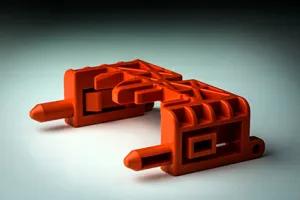

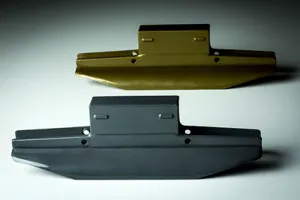

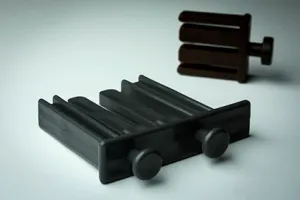

Injected Parts

Our main markets are:

- All

- Veterinary

- Gardening

- Educational Toys

- Electrical and Electronic

- Construction

- Medical

- Haberdashery

- Automotive

- Clean Energy

-

Commercial Refrigeration

-

Construction

-

Electrical and Electronic

-

Medical

-

Metalworking

-

Home

-

Educational Toys

-

Haberdashery

-

Automotive

-

Clean Energy

-

Veterinary

With over 40 years of leadership and national and international certifications, Industrias Carman guarantees plastic injection solutions that exceed your expectations.

Our Services

Always focused on offering quality products and opening new markets, our processes adhere to the most demanding standards, certified by the Mexican Institute for Standardization and Certification A.C., ISO 9001-2015 nationally and internationally.

We accompany you in every stage of your project.

Consulting in materials and engineering designs

We offer expert consulting on materials and engineering designs. Additionally, we have two workshops for mold design and manufacturing, providing an integrated service.

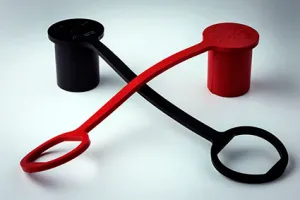

3D Prototypes

As an additional service, Industrias Carman creates 3D prototypes to obtain a part that meets the dimensional and aesthetic requirements requested by our clients, before mold manufacturing. This preliminary step prevents unnecessary costs.

Some of the resins we work with:

-

Polypropylenes – Homo and copolymers. Standard and Filled (Fiberglass, Mineral Fillers, etc.)

-

Polyethylenes (High and Low Density)

-

Nylon 6 and 66 – Standard and Filled (Fiberglass, Mineral Fillers, etc.)

-

Polystyrenes

-

Polycarbonates

-

ABS

-

Acetal Resins (POM)

-

PBT

-

PVC

-

Biopolymers